Pallet Truck Comparison - Manual Hand Pallet Truck Models BASIC and STANDARD

07.02.2023 | Pallet Truck Guidance

In the industrial transport of goods and cargo, manual hand pallet trucks have earned a reputation as "all-rounders" with high versatility. They are generally considered robust and durable, and due to their simple technology, they offer affordable acquisition costs and manageable maintenance requirements. In the market for these practical transport devices, there are countless models for standard Euro pallets and Euro mesh boxes, which have a fundamental similarity in their construction. However, upon closer inspection, differences can often be observed that, within the context of a purchase decision, can play a central role alongside the purchase price and load capacity.

In the Staplerlift.de product range, there are various pallet truck models available at different price levels. We will delve into the differences between an affordable model and a more expensive model as part of a purchase guidance. We will compare the two popular BASIC and STANDARD models in a test and identify the exact differences between the two devices.

Criteria for Comparing Manual Pallet Trucks

Even though manual pallet truck models often look the same and have very similar characteristics at their core, there are often differences affecting their practicality and performance. The following criteria are provided as a guide to effectively compare pallet truck models in practice:

- Maximum load capacity

- Ground clearance

- Size and performance of the hydraulic unit

- Fork width

- Own weight

- Size and shape of the handlebar

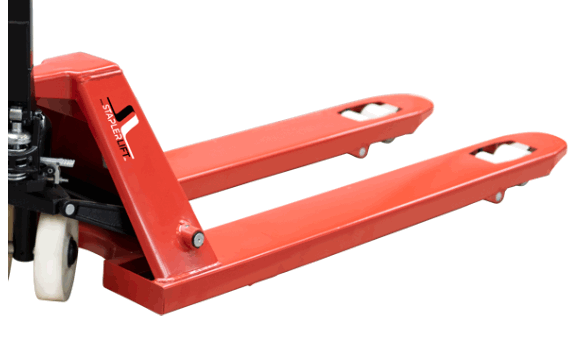

- Fork length

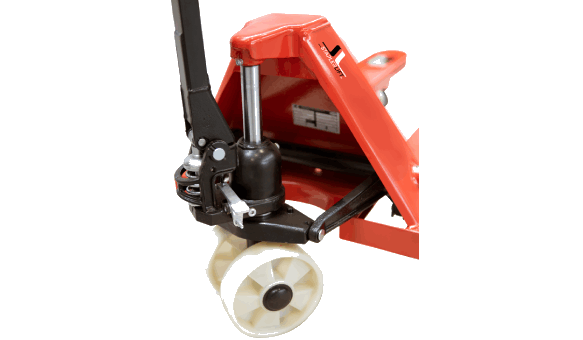

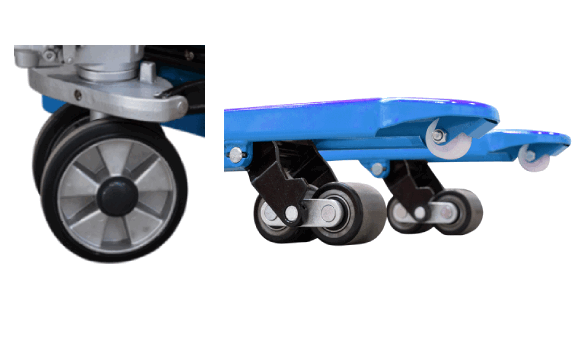

- Type and size of the fork rollers

- Condition of the fork tines and frame

- Minimum and maximum fork height

- Type and size of the steering wheels

- Repair and maintenance options

- Maximum Load Capacity: 2300 kg

- Hydraulic Unit: Basic hydraulic unit without a housing cover

- Handle: Basic design, made of powder-coated steel

- Fork Tines and Main Frame: Powder-coated steel

- Weight: 59 kg

- Minimum Fork Height / Maximum Fork Height / Lifting Range: 85 mm / 200 mm / 115 mm

- Ground Clearance: 30 mm

- Maintenance & Repair Options: Replacement of wear parts such as rollers and wheels, oil change - no direct access to the components of the hydraulic system

- Maximum Load Capacity: 2500 kg

- Hydraulic Unit: High-performance hydraulic unit with screw-on housing cover

- Handle: Reinforced design, made of powder-coated steel, with rubber coating in the grip area, straight-shaped handle sides

- Fork Tines and Main Frame: Powder-coated steel with increased material thickness

- Weight: 69 kg

- Minimum Fork Height / Maximum Fork Height / Lifting Range: 85 mm / 200 mm / 115 mm

- Ground Clearance: 35 mm

- Maintenance & Repair Options: Replacement of wear parts such as rollers and wheels, oil change, direct access to

Hydraulic Lifting Unit - Are There Performance Differences?

One significant difference between the two models is the incorporated hydraulic lifting units. While the BASIC model features a small hydraulic unit in a simple design, the STANDARD model has a larger, high-performance hydraulic unit.

This difference becomes particularly noticeable when lifting loads - the lifting performance per pump stroke is higher in the STANDARD model compared to the BASIC model. Consequently, the high-performance hydraulic unit requires fewer pump strokes to lift the forks by the same lifting distance of 115 mm in both models. This results in a more comfortable and energy-saving way of lifting pallets.

Tiller - How is it Operated?

The deichsel (steering handle) is the element used to implement driving commands and initiate the lifting or lowering process. The deichsel's design significantly influences its operation, and there are differences between the two model variants.

In the BASIC model, the steering and lifting deichsel, made of powder-coated steel, is of a simpler design. In contrast, the STANDARD model features a reinforced deichsel that has a different shape on the left and right grip sides and is coated with sturdy rubber on the grip surfaces. As a result, the STANDARD model is better suited for heavy loads because the rubber-coated grip surface provides a more secure hold and helps prevent hand slipping. The straight-shaped grip sides enhance the maneuverability and drivability, especially when operating the pallet jack from a position slightly to the left or right of the equipment due to limited space.

Forks and Main Frame - Any Differences in Material and Construction?

At first glance, there are no significant differences in the main frame and tines between both manual pallet jack models. However, upon closer inspection, differences in material quality and construction become apparent.

The tines and frame for the lifting unit, made of powder-coated steel, differ in the thickness of the steel used. In terms of load capacity and robustness, the BASIC model makes certain concessions due to its reduced material thickness compared to the STANDARD model.

Gabelrollen and Steering Wheels - How Does the Material and Size Affect Maneuverability?

As the link between the pallet jack chassis and the ground, the pallet jack's tines and steering wheels bear the main load and execute the operator's steering commands. There are differences in the tires of the compared pallet jack models that affect the maneuverability of each model.

The BASIC pallet jack features nylon tires for the tandem load wheels and rubber tires for the steering wheels, designed for smooth and hard surfaces. The STANDARD model comes with polyurethane tandem load wheels paired with rubber steering wheels that are suitable for rough or uneven terrain. Specifically, the STANDARD pallet jack excels in crossing thresholds and uneven surfaces due to its shock-absorbing rubber wheels with a larger diameter. In daily use, the more expensive STANDARD model demonstrates optimal performance on uneven surfaces and low resistance when crossing thresholds. If you want to customize the tires according to your own needs and requirements, the STANDARD CUSTOM pallet jack is an attractive alternative.

The BASIC model is also available with polyurethane tandem load wheels and rubber steering wheels.

Repair and Maintenance Options - Which Parts Can Be Replaced?

Common wear parts such as pallet jack load wheels and steering wheels can be replaced with the appropriate pallet jack replacement parts, as is the case with most pallet jacks on the market. Routine maintenance measures, such as checking the oil level and potentially topping up hydraulic oil, can also be carried out easily on both the BASIC model and the STANDARD model.

However, when it comes to maintenance and repair work on the hydraulic unit itself, a different scenario arises. Unlike the BASIC model, the hydraulic system housing of the STANDARD pallet jack is equipped with a screw-on housing cover that, when opened, allows access to the lifting piston for removal and, thus, permits the replacement of the seals in the hydraulic unit. The maintenance possibilities are therefore severely limited in the BASIC version compared to the STANDARD model.

Applications - It Depends on the Workload

For those considering a manual low lift pallet truck, they will most often need a reliable means of transporting standard European pallets and Euro mesh boxes for daily logistics operations. Although the two compared models meet the requirements for this, when choosing between an inexpensive or more expensive pallet jack model, it usually comes down to the anticipated workload.

Model BASIC - Ideal for Occasional Use

Due to its product characteristics, the BASIC pallet Truck is suitable where the level of use is relatively low:

- In areas with low performance requirements and occasional use with short periods of operation

- In smaller individual businesses such as workshops, craft businesses, retail stores, and more.

- Tasks such as handling individual goods/products, preparing goods for shipping, receiving goods inspections, and more.

Model STANDARD - The Pallet Truck for Almost All Logistics Applications

In areas with high levels of use, the STANDARD pallet jack is well-equipped for almost all logistical transport tasks:

- In areas with increased performance requirements and continuous operation

- In warehousing, logistics, and production areas, in industrial facilities, wholesale businesses, and more.

- Tasks such as warehousing and retrieval, order picking, and shipping handling, and more.

Conclusion – Which Pallet Truck Model Suits Whom?

Pallet Truck BASIC

Advantages:

- Affordable initial cost

- Easy to operate

- High durability for occasional use

Disadvantages:

- Limited repair and maintenance options

- Less flexibility for changing work environments

- Lower durability for intensive usage

Pallet Jack STANDARD

Advantages:

- High performance capability

- Excellent user comfort

- High durability for continuous use

- Good repair and maintenance options

- High flexibility for changing work environments

Disadvantages:

- Higher initial cost

The question of which of the two compared pallet truck models is better suited depends on the individual requirements for use in the workplace.

If someone is looking for an easy-to-use device for short and sporadic tasks and only moves it infrequently at less than full capacity, then, in relation to the purchase cost, the BASIC model is almost always a sustainable and cost-effective solution.

However, if robustness and durability in continuous logistical use are of great importance and the pallet jack is used regularly for heavy loads weighing up to 2500 kg, the STANDARD pallet truck is a high-performance and also a maintenance-friendly tool.