Operating a Pallet Truck – How Does a Pallet Truck Work?

February 17, 2023 | Pallet Truck Guidance

As one of the most popular tools for horizontal load transportation, the pallet truck ensures logistical processes and work procedures in everyday business operations. It has proven itself as a practical means of transportation for decades. Depending on the pallet truck's drive type, the devices differ in operation, but fundamentally, they all serve the same purpose – taking on palletized loads or grid boxes and conveying them to their destination. We'll answer the question of how a pallet truck works and how to operate it correctly. We'll delve into the functions and technology of these practical material handling tools and provide you with useful information for both purchasing and future use.

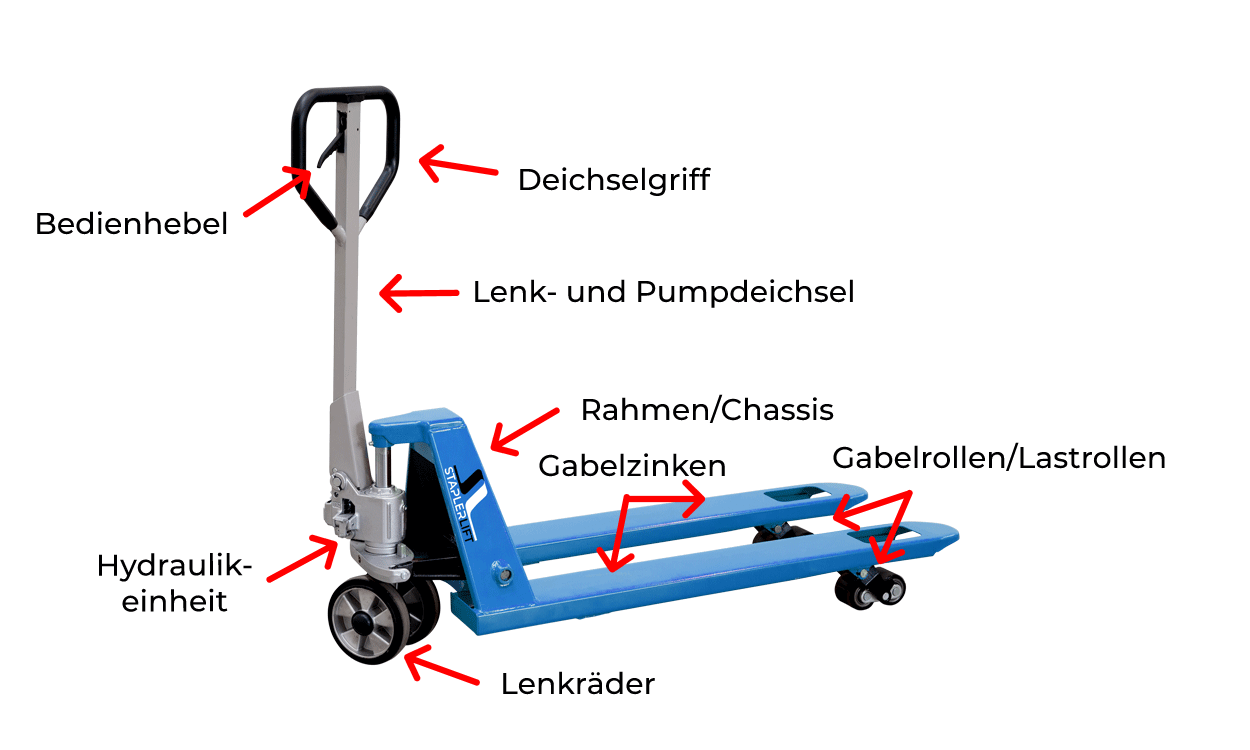

Explaining the Pallet Truck Structure Simply

At first glance, there are no major differences among pallet truck models. All devices share the handle for steering operation, the robust steel chassis with two fork prongs, as well as the steering wheels and fork rollers. However, the individual devices may differ from each other based on certain components and assemblies, primarily related to the various drive types:

Structure and Technology of Manual Pallet Trucks

Components and Functions

- Handle for manual operation

- Control lever for lifting, neutral, and lowering modes

- Steering and pumping handle for lifting, lowering, and executing steering commands

- Frame/Chassis to connect the hydraulic unit, fork prongs, and rollers into a compact unit

- Hydraulic unit for lifting and lowering the fork prongs

- Fork prongs for loading pallets or grid boxes

- Steering wheels for rolling and transmitting steering commands to the floor

- Fork rollers/Load rollers for rolling and supporting the load

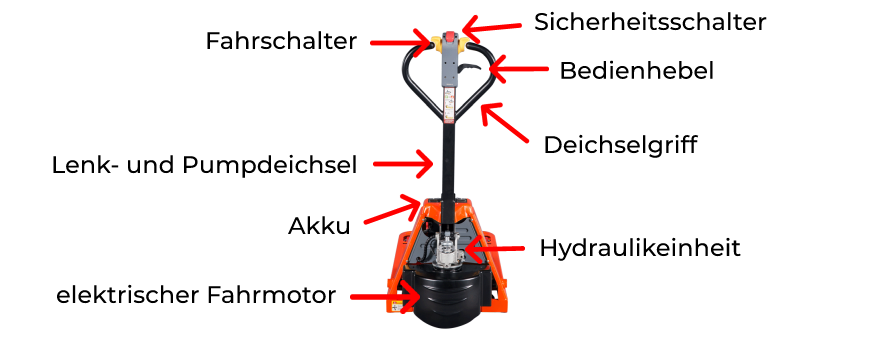

Semi-Electric Pallet Truck

- Drive switch for forward and reverse movement

- Safety switch for braking in case of operator contact

- Control lever to operate the lifting, neutral, and lowering functions

- Handle for manual operation

- Steering and pump handle for lifting and lowering and for steering commands

- Battery to power the electric drive system

- Hydraulic unit for lifting and lowering the fork tines

- Electric drive motor to execute driving commands

Full-Electric Pallet Truck

- Control buttons for operating the lifting and lowering functions

- Electric lifting and drive system for executing driving commands and raising and lowering the fork tines

Pallet Truck Function - What's Behind It?

The basic functions of a classic pallet truck are the lifting function and the driving operation. The handle and the hydraulic unit are the pivot points for the operation and use of the pallet truck in everyday logistics. In manually operated pallet truck models, the technology is limited to the hydraulic lifting unit, while semi-electric models additionally have a driving mechanism. A pallet truck with full electric drive can be used with almost no physical effort, in which both the lifting and driving mechanisms are operated by an electric motor.

To lift loads, a pallet truck must first be completely inserted into the pallet or grid box to be picked up with both forks. After that, the lifting is done in different ways depending on the type of pallet truck:

For manual or semi-electric low lift pallet truck models

- Press the control lever in the handle down to activate the lifting mode

- Operate the hydraulic unit by means of complete pumping movements of the handle

- The kinetic energy is converted into hydraulic energy, and the lifting cylinder connected to the pallet truck chassis acts on the linkage, raising the forks as a result

For fully-electric low lift pallet truck models

- Hold down the control button for the lifting mode

- The electric motor for the lifting drive generates electrical energy, which is converted into hydraulic energy by the hydraulic unit

To lower the forks in manual or semi-electric models, the control lever in the handle or the foot release lever on the hydraulic unit is operated. In fully-electric models, simply press the control button for the lowering mode.

Pallet truck linkage with lowered forks

Pallet truck linkage with raised forks

As a walk-behind industrial truck, you do not need a forklift license to operate a pallet truck with a standard steering handle. The steering handle is the central control unit for executing driving commands during operation. Simply pulling or pushing the handle enables forward or reverse movement, while turning the handle left or right results in a corresponding change in direction during travel.

In most cases, semi-electric or fully electric models have a drive switch integrated into the steering handle, the operation of which is also intuitive. Tilting the switch towards the pallet truck chassis moves the electric pallet truck backward, while tilting the switch in the opposite direction moves the pallet truck forward.

Safety is always the top priority when operating pallet trucks during travel. When paths intersect – for example, in narrow and unclear areas – it is important to always drive forward, allowing you to have visibility regarding potential cross traffic. For this reason, you should never drive in reverse with the fork tines leading into intersecting paths to prevent accidents with potential risks to people and property.

Pallet Truck Special Functions – Optimally Adapted to Specific Applications

The basic functions of a conventional pallet truck are often sufficient for efficiently handling all transport tasks in logistical areas with ease. However, when special environmental conditions need to be considered, special functions significantly facilitate the handling of the pallet truck during transportation and, in many cases, actively enhance safety. For example, pallet trucks with special features, such as a quick-lift function, a pallet truck with a handbrake, or an off-road pallet truck, are designed to suit the specific conditions of the operational environment. Special functions for processes with extended logistical handling steps also provide practical and efficient assistance. These include weighing pallet trucks or scissor lift pallet trucks.